Two-way airflow for all climates

The Hash Hut comes standard with our advanced two-way airflow system. Offering outstanding performance in cold climates. users can easily redirect exhaust heat back to the intake using external recirculation sliders to maintain miner inlet temperatures and prevent snow / ice blockage or ingress. Paired with our quiet, high-reliability variable speed supply fans, this design delivers industry-leading performance and durability in all climates.

One-way airflow for hot climates

We offer the ‘Texas Edition’ airflow configuration on our Hash Hut product line for customers located in hot climates. The Texas Edition leverages a traditional one-way airflow arrangement with our quiet supply fans located on the cold aisle. This arrangement guarantees maximum airflow and miner cooling, while also enabling operational reliability with a positive pressure cold aisle.

SUPERIOR COOLING / HVAC

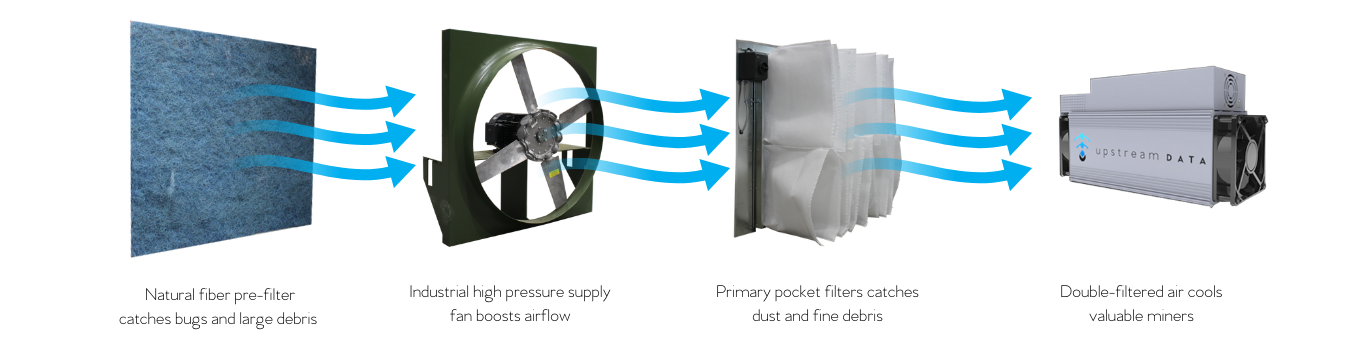

All of our loadcenters come with high performing supply fans to ensure maximum uptime

-

Our supply fans are located in the cold aisle and therefore never overheat or fail from the hot miner exhaust. Each fan is rated for 5 HP complete with high pitch fan blades which are designed to work against high static differential pressure.

Our fans are made with quality, direct drive TEFC cast iron motors, and are VFD controlled. This eliminates unnecessary downtime from broken fan belts and allows our users to dynamically control overall cooling requirements as environmental conditions change.

Unlike exhaust fans which draw a vacuum, our supply fans push positive pressure into the cold aisle which not only improves overall cooling, but prevents moisture leaks from small gaps anywhere in the mining enclosure.

POWER DENSE RACKS

All of our loadcenters come with power dense racks with an integrated PDU and network switch + ethernet

-

Each rack holds up to 24 miners and features replaceable laser cut inserts for hot/cold aisle separation to yield optimal cooling.

Each rack comes with a custom integrated PDU in both smart and basic options, as well as integrated network switches and cables.

QUALITY PDU's

All of our loadcenters come with high performing supply fans to ensure maximum uptime

-

Our supply fans are located in the cold aisle and therefore never overheat or fail from the hot miner exhaust. Each fan is rated for 5 HP complete with high pitch fan blades which are designed to work against high static differential pressure.

Our fans are made with quality, direct drive TEFC cast iron motors, and are VFD controlled. This eliminates unnecessary downtime from broken fan belts and allows our users to dynamically control overall cooling requirements as environmental conditions change.

Unlike exhaust fans which draw a vacuum, our supply fans push positive pressure into the cold aisle which not only improves overall cooling, but prevents moisture leaks from small gaps anywhere in the mining enclosure.

Modular and versatile design fit for any application.

Custom Designs

Need a change? Want a custom color, skid dimension, PDU type, rack arrangement or building attachment? We offer custom manufacturing for customers who need something different.

PRODUCT HIGHLIGHTS / FAQ

Overview:

Unlike brick-and-mortar bitcoin mining facilities, portable bitcoin mining containers have several design constraints that have considerable effect on operational performance and reliability. Power density and reliability are difficult design challenges with portable infrastructure, yet are critical to customer success.

Upstream Data’s product design incorporates lessons learned from over seven years of field experience in the harshest and most remote environments, with hundreds of systems deployed worldwide. Our industry-leading experience is embedded in our products, with key features summarized below.

Get a Quote

We optimize power generation in both the utility power industry and the oil and gas sector.